Our Production Process

The production steps start from the farm itself, which is where the following are done: –

1- Choosing poultry breeds that give high productivity with high quality egg components.

2- Do periodic analyzes and tests of the water that the bird drinks to ensure its safety and suitability

3- Do periodic analyzes of the bird, as well as a detailed autopsy to know the health of the bird and the extent of its ability to produce

4- Choosing organic best fodders from the Egyptian market and choosing the appropriate mixtures to produce a high quality product that will impress our customers.

5- Appointing a veterinarian specialized in poultry health to follow up on vaccinations.

inside our firm:

1- Examination of the farm car at the time of its arrival at the company’s headquarters – making sure that it is clean and disinfected with the permitted disinfectants

2- Sorting and preliminary examination of a sample of eggs to determine the percentage of broken, dirty and deformed eggs

3- Receiving eggs from the farm car and storing them on pallets for the first process.

4- Sorting the eggs to spare the broken and dirty eggs in preparation for a transfer to the main production hall

Inside the production hall

Unloading the eggs on the production lane

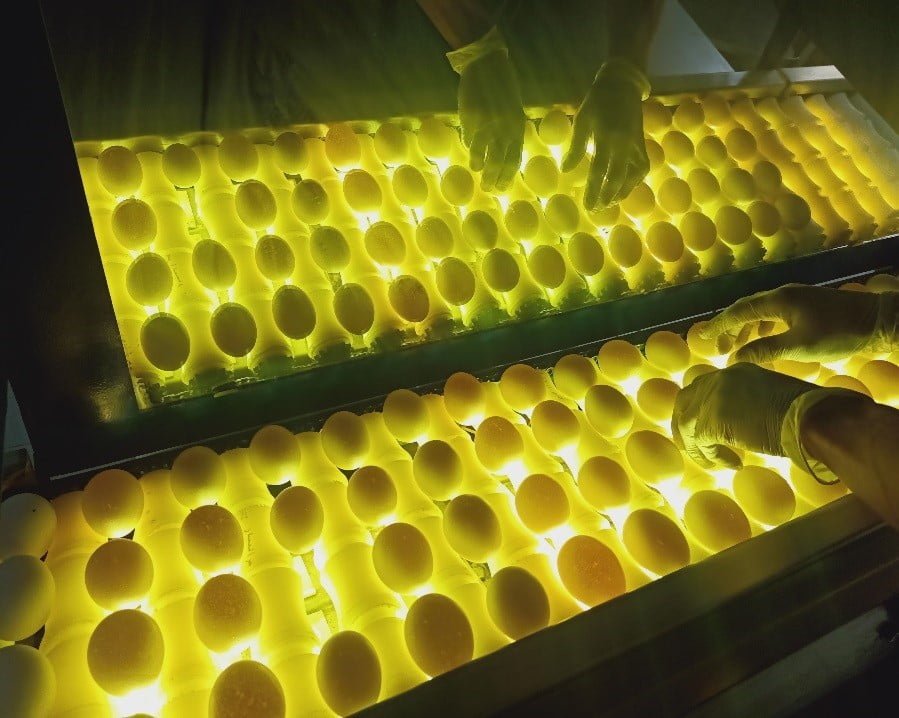

Light examination of eggs to ensure that they are safe and free of internal problems

washing the eggs with ozone and air drying them to ensure spotless eggs

UV sterilizing the eggs to ensure its salmonella free

Stamping the daily date on each egg with special food ink, to ensure our customers receive our products fresh